Science: Chemistry:

Morphology Controlled MoO3/SiO2 Catalyst for Hydrodesulfurization

Seung Hyun Cho and Dr. Jin-Wook Ha+

Department of Chemical Engineering, Soonchunhyang University

ABSTRACT

Several

series of morphologically controlled MoO3/SiO2 catalysts

were prepared, characterized, and tested for hydrodesulfurization (HDS) of dibenzothiophene

(DBT) activity. Molybdenum surface loaded with 4.0 atoms Mo/nm2 was

prepared as sintered hexagonal and sintered orthorhombic, as well as a novel

"well dispersed hexagonal" phase. Characterization by XRD, Raman, and

O2 chemisorption results reveals that the dispersion of MoO3 over

silica depends on the final MoO3 phase in the order of: sintered

hexagonal < sintered orthorhombic < dispersed hexagonal phase. Temperature

programmed reduction (TPR) results show that both bulk and dispersed

microcrystalline of MoO3 reduce to MoO2 at 650C and to Mo metal at 1000C. HDS of DBT was performed in a

differential reactor at 30 atm over the temperature range 350-500C. Activity of MoO3/SiO2

toward HDS of DBT is proportional to dispersion.

Key

Words: Morphology of MoO3/SiO2,

Hydrodesulfurization of Dibenzothiophene

1.

INTRODUCTION

Continual

effort is put into characterization of the types of Mo oxide species which

exist over various supports, their stability, and the optimal preparation

techniques to obtain them. A recent

series of comprehensive works performed with Raman and UV over a number of

supports and supported oxides and with a wide array of preparation procedures

have synthesized many of these concepts into a general theory [1-7]. First, it

was postulated that the surface species of molybdenum present in the air

exposed, hydrated catalyst is only a function of pH in the hydrated layer.

Second, the amount of material deposited in well dispersed form depends on the

number of reactive hydroxyl groups present. In all of the referenced work, MoO3

produced by a calcination at temperatures in excess of 450°C, which produces the well known and

characterized orthorhombic MoO3 phase. The present work with silica

supported MoO3 has centered on investigating, and exploiting the

behavior of the little studied hexagonal phase of MoO3. The

morphology of silica supported catalysts was fully characterized by using XRD,

Raman, BET, and TPR. Activity was tested by hydrodesulfurization

(HDS) of dibenzothiophene (DBT) at 30 atm over the temperature range from 350

to 500C.

The

current study seeks to further characterize the highly dispersed hexagonal

phase and then to establish structure-function relationships for all types of

highly loaded catalysts. It is desired to develop a comprehensive understanding

of the highly loaded catalysts which will complement the current high degree of

understanding of low loading catalyst.

2.

EXPERIMENTAL

2.1 Catalyst Preparation

The

support material used for the preparation of this study was Aerosil 380

(surface area is 380m2/gm), manufactured by Degussa. To densify the

silica, it was wetted with deionized water, dried overnight at room temperature

(24°C),

and then dried at 110°C for 12h in a muffle furnace. Ammonium

hepta-molybdate (IV) tetrahydrate (AHM), (NH4)6Mo7O24.4H2O,

supplied by Aldrich Chemical Company Inc. was used as a precursor. Surface

loading of MoO3 over silica

was 4 atoms Mo/nm2. Loadings were prepared by physically mixing the

desired amount of dry support and precursor, and then adding deionized water to

reach incipient wetness. Acid or base impregnations were conducted with

concentrated nitric acid (2.5N) or ammonium hydroxide (5N) in place of

deionized water. After impregnation the samples were thoroughly stirred and

dried in air overnight.

Table

1. Supported precursor and MoO3

patterns resulting from various preparation conditions for supported MoO3/SiO2

|

Precursor |

Impregnation (Dry T) |

Phase of MoO3 formed |

Calcination Temp.(time) |

Phase of MoO3 formed |

|

AHM/SiO2 |

Acida (25C) |

Hexagonal (NH3)0.15.MoO3.0.5 H2O/SiO2 |

300C (2h) in air |

Hexagonal (sintered wrt precursor) |

|

AHM/SiO2 |

Waterb (25C) |

AHM (NH4)6Mo7O24.4H2O/ SiO2 |

500C (2h) in air |

Orthorhombic (sintered wrt precursor) |

|

AHM/SiO2 |

Basec (25C) |

Triclinic (NH4)2Mo2O7/SiO2 |

300C (2h) in air |

Dispersed Hexagonal |

a Nitric acid,HNO3(2.5N),b Deionized water,H2O(pH=5),c Ammonium hydroxide,NH4OH(5N).

The

final distribution of material appeared homogeneous with the use of watchglasses.

Calcinations were performed in air in a standard muffle furnace. A summary of

sample treatments and final phases of supported MoO3 is given in Table 1. Three different MoO3 phase over

silica will be referred as "SO" for sintered orthorhombic, "SH"

for sintered hexagonal and "DH" for dispersed hexagonal phase of MoO3/SiO2.

2.2 Catalyst Characterization

A

Siemens D 5000 X-ray powder diffractometer was used to identify the various

crystalline phases. Measurements were done at 50 kV, 30 mA, and suitable two

theta range (8-33°), theta step (0.05°) and count

time (3 sec). Raman spectroscopy of catalysts (wet and calcined samples) under

ambient conditions were obtained with an Ar+ laser (Spectra Physics

Model 171) by utilizing about 10-40 mW of the 514.5 nm line for excitation.

Temperature programmed reduction (TPR) was carried at the temperature range

between 400 and 1000°C with 5°C increment.

Reducing gas was 4 vol % of H2 in N2, flowing at 16.8

sccm. Dispersion of MoO3 over SiO2 was estimated by low temperature

(25°C) O2 chemisorption. Activity

for hydrodesulfurization of dibenzothiophene (DBT) was performed in a

differential reactor at 30 atm over the temperature range between 350 and 500C.

3. RESULTS

AND DISCUSSION

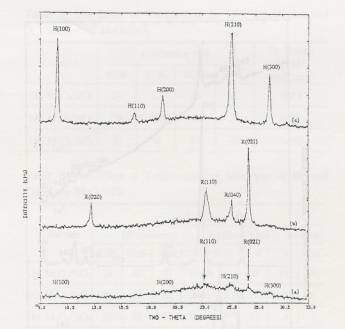

The

effect of the precursor pH (acidic, neutral and basic precursor) and

calcination temperature was studied by XRD and results shown in Figure 1.

Acidic precursor and 300°C calcinations,

sintered hexagonal phase of MoO3 was observed. Sintered

Orthorhombic MoO3 was observed with

neutral precursor and 500°C calcinations.

And for basic precursor and 300°C calcination

samples, both hexagonal and orthorhombic phase of MoO3 was observed.

The

crystallite size of the fraction of crystallites observable by XRD was estimated

from the Scherrer equation to be; 137 Å (SH), 88 Å (SO), and 59 Å (DH), using the

full width at half maximum (FWHM) of the unsupported H(210) (hexagonal phase of

MoO3 crystal) and

R(110) (orthorhombic phase of MoO3 crystal)

phases as standards for instrumental broadening. However, since the integrated

intensities of the DH are well below those of the sintered phases a good

portion of the material also exists as very small(less than 40 Å particles

beyond the detection limit of XRD). These could be amorphous or

microcrystalline. No material was lost through volatilization in this series; a

high degree of crystallinity can be reestablished in the dispersed samples by

subsequent high temperature treatment.

Figure 1. XRD

patterns of calcined 4 atoms Mo/nm2 supported MoO3/SiO2:

(a) basic precursor, 300C calcined in air (DH), (b) neutral

precursor, 500C calcined in air (SO), (c) acid

precursor, 300C calcined in air (SH).

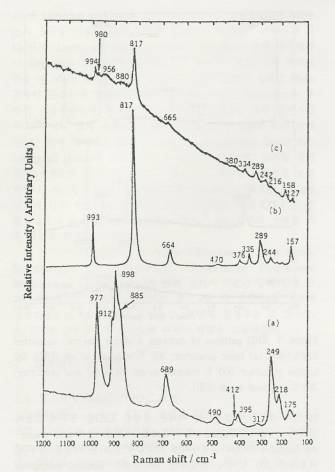

The

Raman spectra of supported MoO3/SiO2 catalysts

under ambient conditions are shown in figure 2. Trends are almost same to XRD

results, a much lesser degree of crystallinity for the well-dispersed hexagonal

sample compared to the sintered hexagonal and orthorhombic.

The

crystalline MoO3 peak is much

more sensitive in Raman than the polymolybdate (Mo7O246-)

peak; even though the intensity is high, the relative amount is low. Wachs'

group has reported that the calcined samples exhibit the very weak Raman

features due to the surface molybdenum oxide species, Mo7O246-

and/or Mo8O264-. It means that dispersed

hexagonal sample actually has less MoO3 crystalline

and more surface molybdenum oxide species, Mo7O246-.

O2

uptake of sulfided MoO3/SiO2 catalysts is given in Table

2. Results also show that dispersion degree of DH is much larger than those of

sintered catalysts (SH and SO).

Table

2. O2 uptake

of 4 atoms Mo/nm2 supported sulfided MoO3/SiO2

catalysts

|

Catalysts |

O2 / MoS2 (mmol / g) |

O2 / Mo (mmol / mmol ) |

|

SH MoO3/SiO2 SO MoO3/SiO2 DH MoO3/SiO2 |

93.86 163.61 289.60 |

0.0150 0.0262 0.0464 |

Figure 2. Raman

spectra of calcined 4 atoms Mo/nm2 supported MoO3/SiO2:

(a) acid precursor, 300C calcined in air (SH), (b) neutral

precursor, 500C calcined in air (SO), (c) basic

precursor, 300C calcined in air (DH).

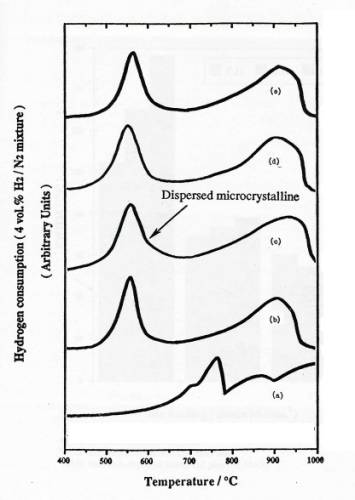

An

initial series of experiments with physically mixed samples were performed to

clarify the interpretation of TPR results. TPR profiles of silica supported MoO3/SiO2 and physical

mixture of MoO3+SiO2

were

shown in figure 3. TPR results show that MoO3 crystal can be

reduced at two regions and the area of the first peak is always close to 1/2

that of the second one.

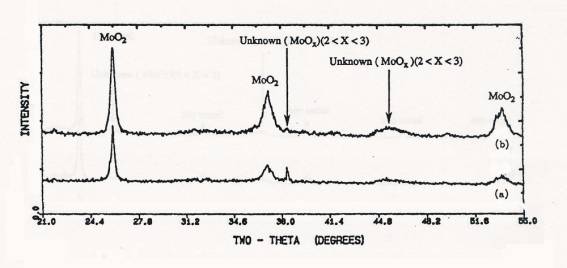

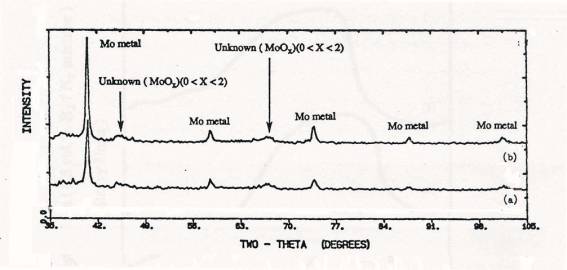

XRD

data taken for the impregnated and physically mixed samples from TPR

experiments stopped at 650°C and 1000°C were shown in figures 4 and 5,

respectively. XRD results showed that MoO3 crystal

reduced to MoO2 by low

temperature reuction and displayed the pattern of metallic Mo after TPR to 1000°C.

Figure 3. TPR

profiles of samples: (a) bulk MoO3, (b) physically mixed 4 atoms

Mo/nm2 MoO3+SiO2, calcined 4 atoms Mo/nm2

supported MoO3/SiO2: (c) basic precursor, 300C calcined in air (DH), (d) acid

precursor, 300C calcined in air (SH), (e) neutral

precursor, 500C calcined in air (SO).

These

results implies that MoO3 crystal reduce

by two step over silica as follows:

MoO3 (both dispersed

and bulk) + H2 ® MoO2 (TPR up to 650°C)

MoO2 (both dispersed

and bulk) + 2H2 ®

Mo (TPR up to 1000°C)

Mo(VI) + 3H2 ® Mo(0) (overall reaction)

The

percentage conversion of DBT and the selectivity to biphenyl (BP) were given in

Tables 3 and 4. The selectivity to BP was

about 80% at temperature ranges from 350 to 400C. However, selectivity to BP was almost

100% at 500C.

Figure 4. XRD

patterns of samples after TPR upto 650C: (a) calcined 4 atoms Mo/nm2

supported MoO3/SiO2(SO), (b) physically mixed 4 atoms Mo/nm2 MoO3+SiO2.

Figure 5. XRD

patterns of samples after TPR upto 1000C: (a) calcined 4 atoms Mo/nm2

supported MoO3/SiO2(SO), (b) physically mixed 4 atoms

Mo/nm2 MoO3+SiO2.

Table 1. Supported precursor and MoO3

patterns resulting from various preparation conditions for supported MoO3/SiO2

Activity

of catalysts toward hydrodesulfurization of DBT is proportional to dispersion

in the order of: sintered hexagonal < sintered orthorhombic < dispersed

hexagonal phase MoO3/ SiO2. TOFs of the

crystalline phases appear higher than that of the dispersed phase. However, the

predominant factor for activity per gram of MoO3 for hydrodesulfurization of DBT is dispersion;

the higher activity of the crystallites does not compensate their lesser

dispersion.

Table 3. The effect of temperature on DBT

conversion and O2 uptake over MoO3/SiO2

|

Catalyst |

Conversion (%) |

O2 uptake O2/Mo(mol/mol) |

|||

|

|

623K |

673K |

723K |

773K |

|

|

SH MoO3/SiO2 |

24 |

27 |

36 |

47 |

0.018 |

|

SO MoO3/SiO2 |

28 |

30 |

42 |

55 |

0.027 |

|

DH MoO3/SiO2 |

32 |

48 |

54 |

74 |

0.048 |

Table 4. The effect of temperature on selectivity

of BP and CHB over MoO3/SiO2

|

Catalyst |

Selectivity (%) |

|||||||

|

|

BP(biphenyl) |

CHB

(cyclohexyl benzene) |

||||||

|

|

623K |

673K |

723K |

773K |

623K |

673K |

723K |

773K |

|

SH MoO3/SiO2 |

79 |

80 |

85 |

91 |

21 |

20 |

15 |

9 |

|

SO MoO3/SiO2 |

81 |

83 |

92 |

98 |

19 |

17 |

8 |

2 |

|

DH MoO3/SiO2 |

82 |

85 |

96 |

99 |

18 |

15 |

4 |

1 |

REFERENCES

1. K. Segawa and W. S. Millman, J. Catal., 77, 221 (1982).

2. L. Wang and W. K. Hall, J. Catal., 77, 232

(1982).

3. F.

J. Gil-Llambias, A. M. Escudey-Castro, and A. Lopez Agudo, J. Catal. 90, 323

(1984).

4. J.

Leyer, M. I. Zaki, Z. Shuxian, and H. Knozinger, Mater. Chem. Phys. 13,

301 (1985).

5. S. J. Moon and S. K. Ihm, Appl. Catal., 42, 307 (1988).

6. A. Datta, J.-W. Ha, and J. R. Regalbuto, J. Catal., 133, 55 (1992).

7. J.-W. Ha, J. of Ind. & Eng. Chemistry, 2(2), 137 (1996).

[ BWW Society Home Page ]

© 2002 The BWW Society/The Institute for the Advancement of Positive Global Solutions